Frontier Technology Quarterly: Frontier technologies for addressing plastic pollution

The severity of plastic pollution is now well-recognized, and countries and communities are looking for innovative solutions for addressing this menace of the modern age. This issue of the Frontier Technology Quarterly shows that new technologies such as nanotechnology, genetic modification and advanced chemical processes can help curb plastic pollution by developing natural substitutes and producing more biodegradable plastics. However, appropriate policies are needed to maximize the potential of new technologies for winning the fight against plastic pollution. Interventions at the production stage will have to be complemented by interventions at other stages of the plastics life cycle, including in usage and disposal, where frontier technologies can play equally important roles.

The plastics threat

Plastic pollution has emerged as the second most ominous threat to the global environment, after climate change. The annual production of plastic has increased from 1.7 million metric tons in 1950 to 322 million metric tons in 2015 (Figure 1). More than eight billion tons of plastic have accumulated on earth. Plastic has become so ubiquitous that some have characterized the current stage of human history as the “Plastics Age.”

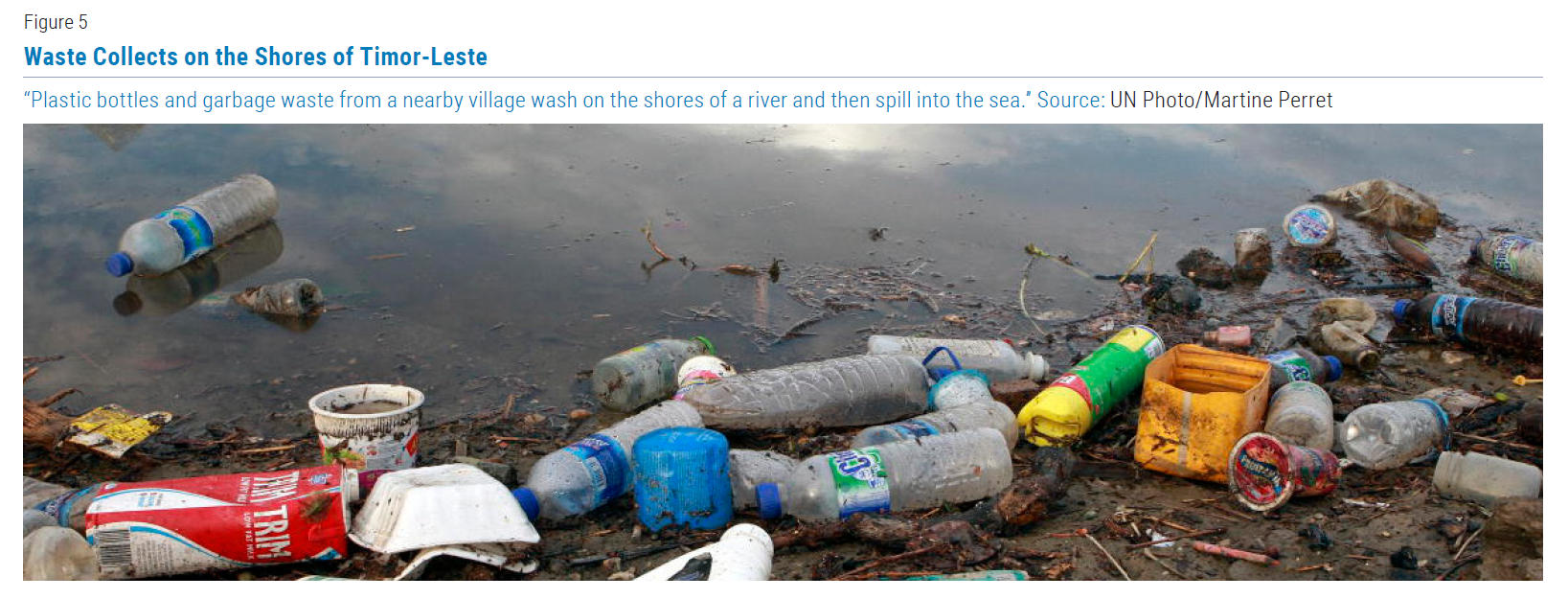

The huge and rapidly rising volume of plastics is harming the environment and human health. This is because most of the plastics produced and accumulated so far are non-biodegradable. When plastic is disposed in landfills, it contaminates the surrounding land area. When incinerated, it pollutes the air, in addition to the impact from generating the energy used in the process. If disposed in bodies of water, not only does it contaminate but also becomes a threat to all aquatic life forms. Much of the plastic waste has ended up in the oceans, with estimates ranging from 93 to 236 thousand metric tons floating in the oceans (Figure 2). Plastic is increasingly invading the food chain, with birds and animals directly and indirectly consuming vast amounts of plastic. It is estimated that 90 per cent of seabirds have ingested plastic debris (Freedman, 2016; Mathieu-Denoncourt, et al., 2015). According to a 2017 study, 83 per cent of tap water samples from across the world contained plastic pollutants. As plastic products are not properly disposed, micro plastic debris is entering the air directly, contributing to respiratory problems. Plastics are also a major source for

The huge and rapidly rising volume of plastics is harming the environment and human health. This is because most of the plastics produced and accumulated so far are non-biodegradable. When plastic is disposed in landfills, it contaminates the surrounding land area. When incinerated, it pollutes the air, in addition to the impact from generating the energy used in the process. If disposed in bodies of water, not only does it contaminate but also becomes a threat to all aquatic life forms. Much of the plastic waste has ended up in the oceans, with estimates ranging from 93 to 236 thousand metric tons floating in the oceans (Figure 2). Plastic is increasingly invading the food chain, with birds and animals directly and indirectly consuming vast amounts of plastic. It is estimated that 90 per cent of seabirds have ingested plastic debris (Freedman, 2016; Mathieu-Denoncourt, et al., 2015). According to a 2017 study, 83 per cent of tap water samples from across the world contained plastic pollutants. As plastic products are not properly disposed, micro plastic debris is entering the air directly, contributing to respiratory problems. Plastics are also a major source for

CO₂ emissions.

Five stages of intervention to confront plastic pollution

Five stages of intervention to confront plastic pollution

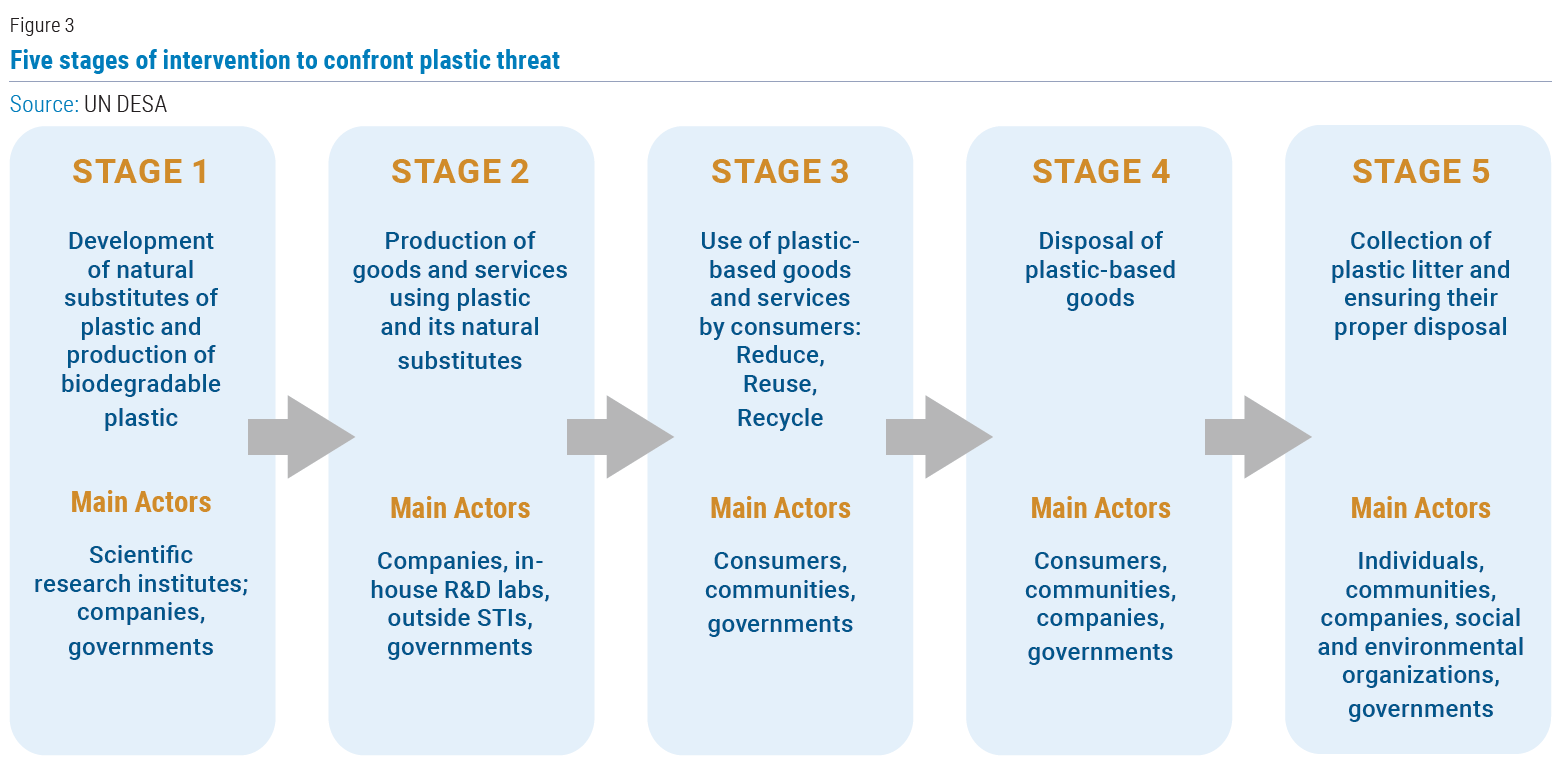

The seriousness of the plastic threat is well-recognized by now. It is possible to identify five different stages where interventions can be made to contain, reduce, and eliminate plastic pollution (Figure 3). In Stage 1, it is possible to replace some plastics by natural substitutes and, in cases where use of plastic is unavoidable, to use the more biodegradable ones. In Stage 2, where plastics are used to produce actual goods and services, it is possible to find ways to reduce its use. Stage 3 is where the consumer uses plastics-based products and services and can “reduce,” “reuse,” and “recycle” to reduce the demand for new plastics. Stage 4 involves the disposal of plastics-based products. There are many options at this stage, some of which are more environment-friendly than others. The fifth and final stage involves the proper collection and disposal of plastic waste in order to ensure less harm to the environment. The role of main actors at these different stages vary, as indicated in Figure 3. Interventions at all the five stages are necessary to reduce and mitigate plastic pollution.

Developing natural substitutes for plastic

Plastics are a relatively new substance, and in the past, life was possible without plastic. In the pre-plastics age, natural products were used to meet many of the needs that plastics currently meet. Replacing plastics with their natural substitutes is clearly the “first-best” solution for addressing plastic pollution. In many cases, this substitution is quite straightforward and does not require any new technology. For example, it is possible to return to the use of cloth tote bags for shopping, or to the use of banana leaves to wrap and transport food, with minimal technological innovation (Figure 4). However, in other cases, plastics offer some new, desirable properties—such as water-resistance, non-permeability, lightness, durability, etc.—that natural substitutes cannot provide at a reasonable cost, unless some technologies can impart similar properties to them. It is encouraging that frontier technologies can help in doing so. The following provides a few examples.

Nanotechnology for cardboard and paper materials

Nanotechnology for cardboard and paper materials

Non-plastic materials—such as cardboard, paper and other products—have long been used in packaging, and nanotechnology can help in making these more capable to protect items being transported. For example, cardboard can be coated with new water-resistant materials to prevent leaks or damage to food and other perishable products. Nanotechnology allows such coatings to be made thinner and more cost effective. Use of nanomaterials can provide barriers coated on the packaging as well as the use of anti-microbial nanomaterials directly on perishable products to protect them. Also, ‘smart packaging’ which incorporates nanosensors, time-temperature indicators, oxygen sensors, and freshness indicators, allows monitoring of the environmental, biochemical and microbial changes in food items, flagging needed interventions and adaptions (Sharma, et al., 2017).

One practical example of using nanotechnology on thin paper and cardboard lining is provided by a Finnish firm, which developed a fully recyclable coating for paper cups that can hold hot beverages for more than two days (Material District, 2017). Nanotechnology is also helping cardboard box materials be more attractive for branding, thus competing with plastic packaging. There are, for example, nano-based images and coatings that are thin and sturdy, and can be laminated, rather than fused into surfaces. These are also less material-intensive and have lower costs (Mohan, 2017). Innovations are even looking beyond wood-pulp cardboard box to more ecological materials, including edamame beans, cocoa beans and waste hazelnuts (ibid).

Genetic engineering of hemp and other materials

Advances in genetic engineering show considerable prospects of promoting natural substitutes of plastics. In particular, it is helping many natural fibers, such as hemp, flax and jute to acquire properties that can make them better substitutes for plastics. The hemp plant has been the basis of fabrics, textiles, materials, medication, parchments, currency and other uses throughout history, and modern technology is expanding the use of hemp further. These bioengineering methods can help to enhance other crops, such as flax and jute, to compete with plastics on sturdiness, weight and yield. Innovations with flax include Flaxstic™, a combination of flax straw waste, plant-based biopolymers and recycled materials (Pelcase, 2019). Similarly, sequencing of the jute genome in 2010 has opened up new possibilities for its uses, including for various packaging. For example, bonding of jute fiber cellulose and soy resin protein has been utilized to produce a sturdy bio-composite, called jute-soy, which is biodegradable (Behera, et al., 2012).

Nanotechnology for producing lightweight steel and altered aluminum

Nanotechnology is also used to produce lightweight steel and aluminum that can compete with plastics. For example, researchers at Purdue University are altering the microstructure of aluminum in order to increase its strength, through layering “stacking faults,” or distortions in the structure by removing atomic layers using laser only tens of nanometers in width, which can have a variety of industrial applications (Venere, 2018). These developments can be significant. In the auto industry, for example, under the current scenario, average plastic content in each automobile is expected to grow from 200 kg in 2014 to 350 kg by 2020 (Plastics Today, 2015). Use of lightweight steel and aluminum as substitutes for plastic has the further advantage that, unlike the latter, the former can be relatively easily reused and recycled. These innovations have allowed a US car manufacturer to introduce a remodeled pickup truck in 2014, the first all-aluminum body truck. On a smaller scale, reusable aluminum bottles and cups have emerged as an alternative to plastics, and even metal foils for packaging and wrapping purposes.

Producing biodegradable plastics

The main reason why plastics are a threat to the environment is that they are generally not biodegradable (Figure 5). If finding natural substitutes is the “first-best” solution of the plastics threat, the “second-best” solution is making plastics biodegradable. Such plastics biodegrade either under natural conditions or when subjected to some simple processes, such as chemical hydrolysis, application of heat, photodegradation, or composting. They may be derived either from renewable biomass (plants or animal resources) such as starch, cellulose, chitosan and protein or from fossil fuels. However, most of the biodegradable plastics are from biomass. It is encouraging that frontier technologies can play an important role in making both bio-based and fossil-based plastics more biodegradable.

Advanced chemical processes

Among the most commonly known bio-based biodegradable polymers, polylactide (PLA) is considered the most promising. It is produced from lactic acid derived from sugar beets, sugar cane and corn. Its proven mechanical strength and low toxicity have already led to PLA’s successful implementation in packaging, textiles, oil and gas, electronics, 3D printing and biomedical applications (Luckachan and Pillai, 2011). To relieve pressure on resources necessary for food crops, a company from the Netherlands has developed PLA from second generation feedstocks such as bagasse, corn stover, wheat straw, and wood chips, which are not suitable for human consumption (Corbion, 2016). Polylhydroxyalkanoates (PHAs) are another bio-based and biodegradable polymer group, which is proven useful in coating and packaging. Owing to their additional biocompatibility feature, they can also be used for medical purposes.

Genetic modifications for biodegradability

Currently, starch and cellulose are the two main bio-materials used to produce bio-based biodegradable plastics. However, both have limitations. For example, starch has poor mechanical properties. It is water-soluble and so it gets degraded when processed by wet-based routes. Similarly, cellulose-based plastic does not perform well in its natural form. To overcome these limitations, they are often mixed with high-performance synthetic polymers. Mixing with these polymers however decreases their biodegradability. Genetic modifications can help to avoid this conundrum. For example, genetically engineered corn, barley and rice provide sturdier starch compared to starch derived from traditional crops.

Nanotechnology for biodegradability

Incorporation of nanotechnology into the production process of bioplastics for the creation of nanostructures provides an innovative approach to creating a new range of biomaterials. Researchers in recent years have shown that nanotechnology can improve the properties of biodegradable plastics. A Japanese research group proved that mixing PLA with nanocellulose can accelerate the process of biodegradation while maintaining its mechanical strength (Green Science Alliance, 2019). While it is a very recent technology, nanocellulose has the potential to be used in several areas, including paper, packaging, medical, cosmetic, and pharmaceutical applications, coating, and computer components. In the paper and paperboard making industry, nanocellulose acts as an additive material to enhance the paper’s density and strength. It also improves the print quality by providing smooth surfaces for printing. In recent years, transparent nanocellulose paper has gained much attention in the field of electronics because it is cost-efficient, light-weight, biodegradable, recyclable and possesses desired optical properties. It finds application in such areas as mobile phones, computers, TVs, touch sensors, solar cells, and paper-based generators (Prescouter, 2019). As nanocellulose is transparent, light, strong and flexible, technology companies are experimenting with it to make flexible screens that are more environmentally sustainable.

Use of nanotechnology in the production of bioplastics is not limited to the composites. It also offers new techniques for blending polymers. Conventional blending methods are limiting in blending incompatible polymer partners, due to different physical properties. Nanostructure blending overcomes these limitations and results in polymers with better mechanical properties (Mohanty and Bhardwaj, 2009).

Policy implications

This Quarterly shows that frontier technologies hold considerable prospects for mitigating plastic pollution. Nanotechnology, genetic engineering, advanced chemical processes and advanced engineering can make better natural substitutes for plastics and make plastics more biodegradable. However, whether this potential of frontier technologies materializes or not depends to a large extent on government policies.

Many of the technological solutions discussed here are expensive, at least during the early stage of development and use. For example, PHAs are bio-based, biodegradable and biocompatible. However, their production costs are high, ranging from $2.6 to $5.5 per kilogram (Corbion, 2016). High per unit production costs are restrictive and consequently hinders reaching the scale of production needed to bring costs down. Initial government support is necessary to break this vicious cycle. This support can take various forms. Concessional financing through dedicated banks, financial institutions and financing methods as well as subsidies can allow the production scale to expand. Aligning incentives to counteract the advantage enjoyed by the incumbent conventional plastics producers—by imposing fines or taxes on their products, or increasing the liability of producers for the environmentally safe disposal of the plastics they produce, etc.—can also spur the development and use of viable alternatives. Outright administrative measures, such as restricting or banning the use of conventional plastics can also be used (Figure 6). The government can also help through its procurement programmes, giving

preference to products made with plastic substitutes and biodegradable plastics.

Governments can help to promote public sector research on plastics by establishing research institutes, creating industrial clusters, and supporting public-private partnerships. Governments can also help through improved coordination. For example, it can link producers with prospective consumers. The coordinating role of the government can be helpful in other contexts as well. Though technologies are available for production of ultralight steel or aluminum that can counteract the advantage that plastics have in terms of weight, these require larger amounts of electricity. Thus, unless the necessary additional electricity is obtained from renewable sources, environmental benefit from reduced plastics pollution may be more than offset by the increase in emissions resulting from additional electricity consumption. The government can help to counteract such adverse tradeoffs by coordinating and facilitating the switch to renewables.

Cooperation at the international level, involving both governments and corporations is necessary for promoting the transfer of technologies needed for plastic substitutes and biodegradable plastics. Going forward, closely studying the economic dynamics of moving towards plastic substitutes at further stages of the plastics cycle will help countries and communities determine the right mix of policies and incentives to fight the plastic menace head-on.

References

Behera, A. K., et al. (2012). Fabrication and characterizations of biodegradable jute reinforced soy based green composites. Carbohydrate Polymers, 88(1): 329-335.

Corbion (2016). PLA Bioplastics. Available from https://www.corbion.com/media/75646/corbion_bioplastics_brochure.pdf. Accessed on 3 July 2019.

Freedman, Jeremy (2016). Turning rubbish into money—environmental innovation leads the way. 29 February. Available from https://globalnomadic.com/turning-rubbish-into-money-environmental-innovation-leads-the-way/.

Green Science Alliance (2019). Nanocellulose+PLA Composite Material. Available from https://www.gsalliance.co.jp/en/wp-content/uploads/2019/06/CNF-PLA-E.pdf. Accessed on 30 July 2019.

Jambeck, Jenna R. (2017). Role of technology in reducing plastic waste and production. Background Paper for World Economic and Social Survey 2018: Frontier technologies for sustainable development, UN Publications, Sales No. 18.II.C.1.

Luckachan, G. E., and C. K. S. Pillai (2011). Biodegradable polymers: A review on recent trends and emerging perspectives, Journal of Polymers and the Environment, 19(3):637-676.

Material District (2017). Isla plastic-free paper cup coating is completely recyclable. 26 October. Available from https://materialdistrict.com/article/isla-paper-cup-coating-recyclable/. Accessed 26 August 2019.

Mathieu-Denoncourt, Justine, et al., (2015). Plasticizer endocrine disruption: Highlighting developmental and reproductive effects in mammals and non-mammalian aquatic species. General and Comparative Endocrinology, vol. 219 (August), pp. 74–88.

Mohan, A.M. (2017). Four technology advances reshaping the folding cartons market. Packaging World. 24 September 2017. Available from https://www.packworld.com/article/package-type/cartons-and-boxes/folding-carton/four-technology-advances-reshaping-folding. Accessed 26 August 2019.

Mohanty, Amar, and Rahul Bhardwaj (2009). Nanostructure controlled bioplastics in the design and engineering of sustainable multifunctional green materials. ICCM International Conferences on Composite Materials.

Pelcase (2019). What is Flaxstic? Available from https://pelacase.com/pages/what-is-flaxstic . Accessed 26 August 2019.

Plastics Today (2015). Plastics use in vehicles to grow 75% by 2020, says industry watcher. Available from https://www.plasticstoday.com/automotive-and-mobility/plastics-use-vehicles-grow-75-2020-says-industry-watcher/63791493722019. Accessed on 26 August 2019.

Prescouter (2019). What are the applications of nanocellulose in packaging? Available from https://www.prescouter.com/2018/02/nanocellulose-applications-packaging/. Accessed on 30 July 2019.

Schluttenhofer, C., and L. Yuan (2017). Challenges towards revitalizing hemp: A multifaceted crop, Trends in Plant Science, 22(11): 917-929.

Sharma, C., et al. (2017). Nanotechnology: An Untapped resource for food packaging, Frontiers in Microbiology, 8: 1735.

Sutter, John D. (2016). How to stop the sixth mass extinction. CNN. Accessed on 18 September 2019.

Venere, E. (2018). New research yields super-strong aluminium alloy. Purdue University. January. Available from https://phys.org/news/2018-01-yields-super-strong-aluminum-alloy.html. Accessed on 26 August 2019.

Follow Us